- Call us today: 01923 725 180

- sales@epicinsulation.co.uk

Acoustic Solution - Concrete Separating Floor

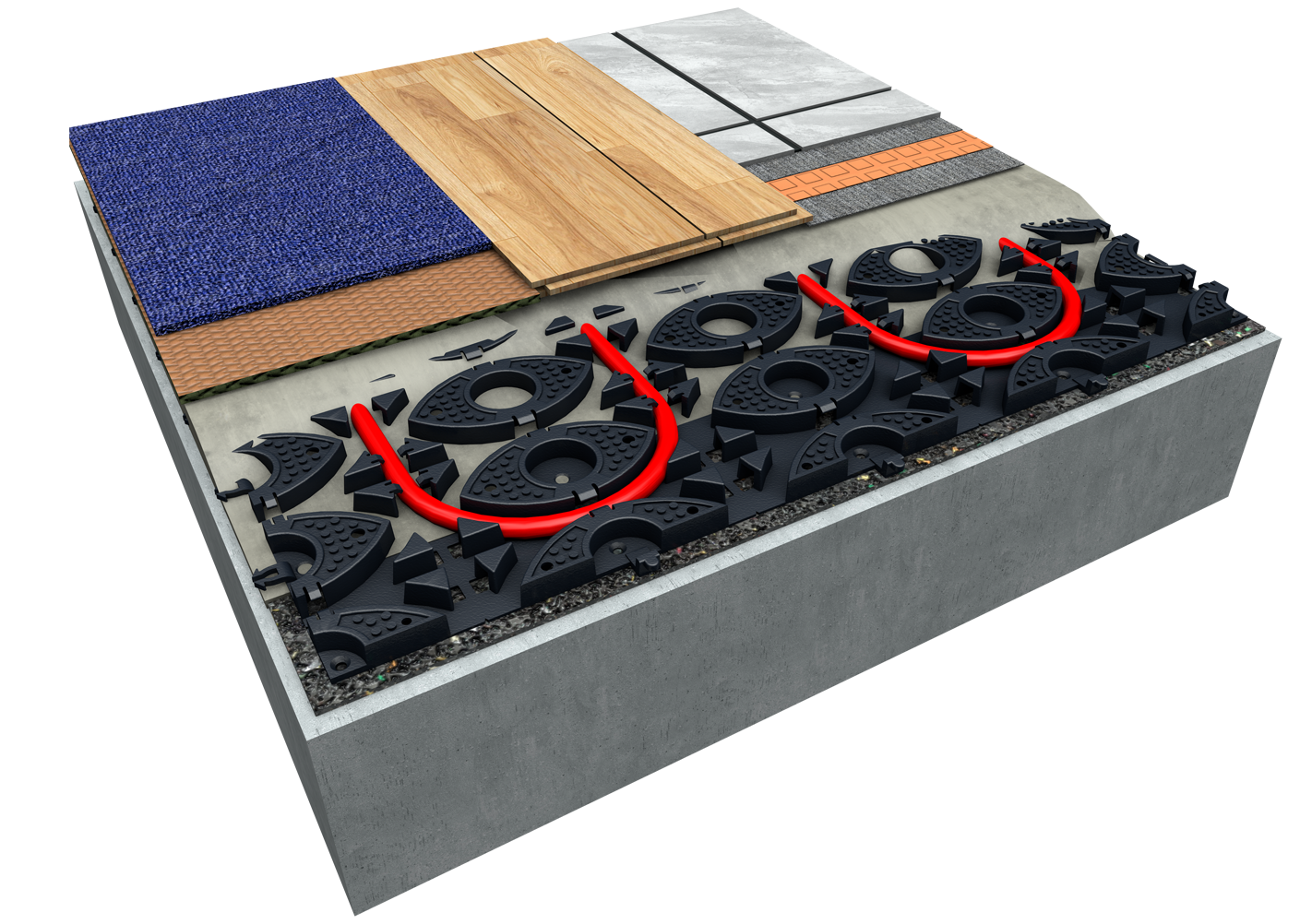

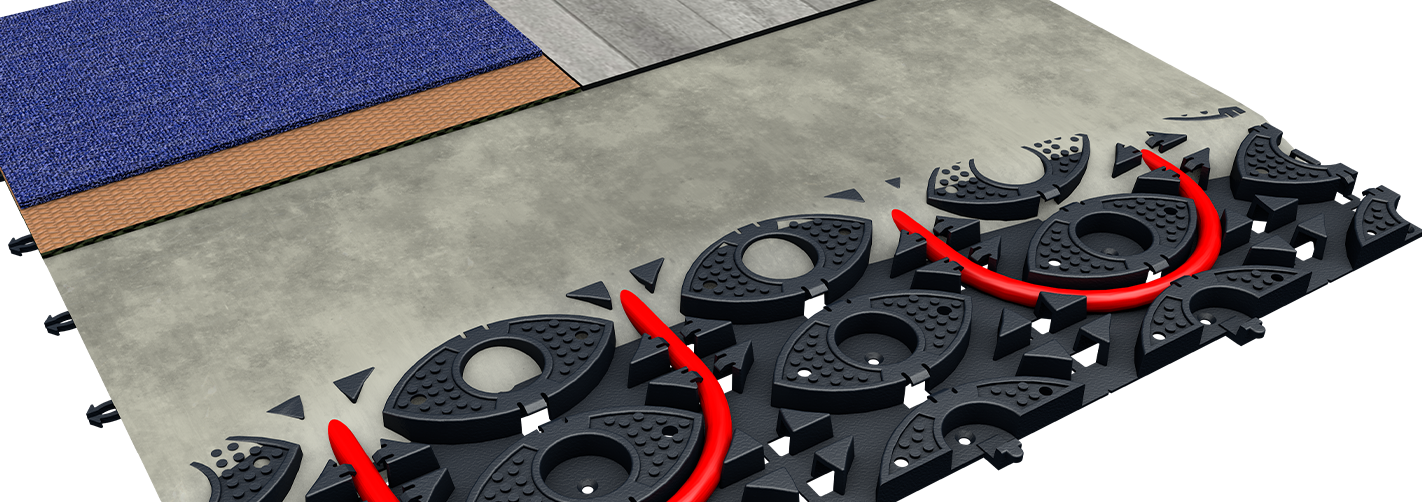

The Profix® Ultra-Low-Profile Screed System can be installed onto a thin IsoRubber resilient acoustic isolation material to create a very thin pipe-in-screed warm-water underfloor heating solution that delivers high heat outputs and fast system response times with the additional benefit of airborne and impact noise reduction.

This system combines the Profix® panel with a quick drying cement-based levelling compound for fast-track results.

Thanks to the unique design and strength of the patented Profix® panel, for normal duty residential and commercial applications, a minimum screed thickness of just 20mm is required for cement-based levelling compounds*

* 30 N/mm² minimum compressive strength (after 28 days)

5 N/mm² minimum flexural strength (after 28 days)

The below video demonstrates how the Profix® Ultra-Low-Profile Screed System, installed onto a thin IsoRubber resilient sound isolation material on a concrete separating floor, creates a very thin pipe-in-screed warm-water underfloor heating system with impact noise reduction.

Heat Output Table

| MEAN WATER TEMPERATURE | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 300 | 300 | 350 | 350 | 400 | 400 | 450 | 450 | 500 | 500 | ||

| SYSTEM TYPE |

FLOOR COVERING | Heat Output W/m2 | Floor Surface Temp oC | Heat Output W/m2 | Floor Surface Temp oC | Heat Output W/m2 | Floor Surface Temp oC | Heat Output W/m2 | Floor Surface Temp oC | Heat Output W/m2 | Floor Surface Temp oC |

| Profix® Ultra-Low-Profile Screed - Concrete Separating Floor | Tiles | 56.6 | 25.2 | 84.9 | 27.8 | 113.2 | 30.4 | 141.5 | 33.1 | 169.8 | 35.7 |

| LVT | 40.2 | 23.7 | 60.3 | 25.6 | 80.4 | 27.4 | 100.5 | 29.3 | 120.6 | 31.1 | |

| 15mm Engineered Wood | 37.0 | 23.4 | 54.0 | 25.1 | 73.0 | 26.4 | 91.3 | 28.2 | 109.8 | 30.1 | |

| Carpet & Underlay (1.5 TOG) | 30.0 | 22.8 | 45.0 | 24.1 | 60.0 | 25.5 | 75.0 | 26.9 | 90.0 | 28.3 | |

*For Guidance only - all systems must conform to BS EN 1264

| Heat Output Table | |

|---|---|

| SYSTEM TYPE |

Profix® Ultra-Low-Profile Screed - Concrete Separating Floor |

| FLOOR COVERING | Tiles |

| MEAN WATER TEMPERATURE |

DESCRIPTION | VALUE |

|---|---|---|

| 300 | Heat Output W/m<sup>2</sup>2 | 56.6 |

| 300 | Floor Surface Temp <sup>o</sup>C | 25.2 |

| 300 | Heat Output W/m<sup>2</sup>2 | 84.9 |

| 300 | Floor Surface Temp <sup>o</sup>C | 27.8 |

| 350 | Heat Output W/m<sup>2</sup>2 | 113.2 |

| 350 | Floor Surface Temp <sup>o</sup>C | 30.4 |

| 350 | Heat Output W/m<sup>2</sup>2 | 141.5 |

| 350 | Floor Surface Temp <sup>o</sup>C | 33.1 |

| 400 | Heat Output W/m<sup>2</sup>2 | 169.8 |

| 400 | Floor Surface Temp <sup>o</sup>C | 35.7 |

| Heat Output Table | |

|---|---|

| SYSTEM TYPE |

Profix® Ultra-Low-Profile Screed - Concrete Separating Floor |

| FLOOR COVERING | LVT |

| MEAN WATER TEMPERATURE |

DESCRIPTION | VALUE |

|---|---|---|

| 300 | Heat Output W/m<sup>2</sup>2 | 40.2 |

| 300 | Floor Surface Temp <sup>o</sup>C | 23.7 |

| 300 | Heat Output W/m<sup>2</sup>2 | 60.3 |

| 300 | Floor Surface Temp <sup>o</sup>C | 25.6 |

| 350 | Heat Output W/m<sup>2</sup>2 | 80.4 |

| 350 | Floor Surface Temp <sup>o</sup>C | 27.4 |

| 350 | Heat Output W/m<sup>2</sup>2 | 100.5 |

| 350 | Floor Surface Temp <sup>o</sup>C | 29.3 |

| 400 | Heat Output W/m<sup>2</sup>2 | 120.6 |

| 400 | Floor Surface Temp <sup>o</sup>C | 31.1 |

| Heat Output Table | |

|---|---|

| SYSTEM TYPE |

Profix® Ultra-Low-Profile Screed - Concrete Separating Floor |

| FLOOR COVERING | 15mm Engineered Wood |

| MEAN WATER TEMPERATURE |

DESCRIPTION | VALUE |

|---|---|---|

| 300 | Heat Output W/m<sup>2</sup>2 | 37.0 |

| 300 | Floor Surface Temp <sup>o</sup>C | 23.4 |

| 300 | Heat Output W/m<sup>2</sup>2 | 54.0 |

| 300 | Floor Surface Temp <sup>o</sup>C | 25.1 |

| 350 | Heat Output W/m<sup>2</sup>2 | 73.0 |

| 350 | Floor Surface Temp <sup>o</sup>C | 26.4 |

| 350 | Heat Output W/m<sup>2</sup>2 | 91.3 |

| 350 | Floor Surface Temp <sup>o</sup>C | 28.2 |

| 400 | Heat Output W/m<sup>2</sup>2 | 109.8 |

| 400 | Floor Surface Temp <sup>o</sup>C | 30.1 |

| Heat Output Table | |

|---|---|

| SYSTEM TYPE |

Profix® Ultra-Low-Profile Screed - Concrete Separating Floor |

| FLOOR COVERING | Carpet & Underlay (1.5 TOG) |

| MEAN WATER TEMPERATURE |

DESCRIPTION | VALUE |

|---|---|---|

| 300 | Heat Output W/m<sup>2</sup>2 | 30.0 |

| 300 | Floor Surface Temp <sup>o</sup>C | 22.8 |

| 300 | Heat Output W/m<sup>2</sup>2 | 45.0 |

| 300 | Floor Surface Temp <sup>o</sup>C | 24.1 |

| 350 | Heat Output W/m<sup>2</sup>2 | 60.0 |

| 350 | Floor Surface Temp <sup>o</sup>C | 25.5 |

| 350 | Heat Output W/m<sup>2</sup>2 | 75.0 |

| 350 | Floor Surface Temp <sup>o</sup>C | 26.9 |

| 400 | Heat Output W/m<sup>2</sup>2 | 90.0 |

| 400 | Floor Surface Temp <sup>o</sup>C | 28.3 |

*For Guidance only - all systems must conform to BS EN 1264

Fast Installation

The self-adhesive backed Profix® panels feature multiple pipe retention clips to hold the 10 – 12mm diameter pipe securely in place. In addition, the panels fasten together thanks to purpose made locking features included in the design.

In order to ensure a good quality installation, it is essential the structural sub-floor is < 75% RH (BS 8203 : 2017), otherwise first a liquid DPM will need to be applied, and that it is flat and free from stepped or uneven areas . This can be achieved by using a pre-levelling system, such as a self-smoothing compound. Whilst these measures will add some time and cost, they should avoid any issues later which could be considerably more disruptive and expensive to rectify.

Twenty-four hours before installation, the IsoRubber should be rolled out loosely into position to acclimatise. Once acclimatised, the IsoRubber should be lifted and an even layer of Isobond adhesive applied to the level sub-floor. This should be left for approximately 20 minutes or until the Isobond becomes tacky, before laying the IsoRubber. For very porous surfaces, a water-based PVA primer should be applied before applying the Isobond adhesive.

The IsoRubber should be fitted with all joints tightly butted and up against the perimeter walls or other vertical upstands. The surface should be smoothed using a roller to ensure good adhesion with no air bubbles.

Self-adhesive backed Profix® PE Perimeter Insulation should then be applied to all walls and other vertical upstands before laying the self-adhesive backed Profix® panels onto the IsoRubber.

Floor Coverings

The Profix® Ultra-Low-Profile Screed System installed onto a thin IsoRubber resilient acoustic isolation material creates a very thin pipe-in-screed warm-water acoustic underfloor heating solution suitable for a wide range of different floor coverings. Thanks to the inclusion of a cement-based levelling compound, drying times are significantly reduced compared to thicker wet screed systems.

The unique design and strength of the patented Profix® Panel means that for normal duty residential and commercial applications a minimum screed thickness of just 20mm is required for cement-based levelling compounds*

* 30 N/mm² minimum compressive strength (after 28 days)

5 N/mm² minimum flexural strength (after 28 days)

Furthermore, in good drying conditions light foot traffic should be possible after just 4 hours and final floor coverings can be applied after just 24 hours, depending on the type of floor covering chosen.

The ultra-smooth, low deflection surface requires no over-boarding so you can simply lay your chosen floor covering directly on top.

Tiles or Engineered Wood

For Tile or Engineered Wood floor coverings, when using a qualifying cement-based levelling compound, a minimum underfloor heating screed depth of 20mm will be required.

Carpet or Luxury Vinyl

For Carpet or Vinyl floor coverings, when using a qualifying cement-based levelling compound, a minimum underfloor heating screed depth of 20mm will be required.

Benefits

Very Thin System

Underfloor Heating and Acoustic Performance Combined in One Solution

Can Assist in Achieving Approved Document Part E Compliance

High Heat Outputs Even at Low Water Temperatures

Heats Up Faster than Standard Systems

Rapid Drying Times

Suitable for a Range of Floor Coverings

No Over-boarding Required – Simply Lay Final Floor Coverings Directly On Top

How To Buy

Looking to buy? Click below to discover more about finding (or becoming) a stockist/reseller.

FIND OUT MORE